PRODUCT

Fashion fabrics

Innovative gloss fabric

ULTRA RUGANO

Development history

Since August 2007, we have been selling "RUGANO™," a top quality lacquer-tone material. During this time, we have been continuing to develop a special material with gloss, and in recent years, major customers have been calling for a gloss that is better than our conventional "RUGANO™." As a result, we pursued to improve our gloss while maintaining the characteristics of our conventional "RUGANO™" (1. no flattening, 2. no hardening, 3. drape maintenance, 4. gloss and washing durability). We accepted this challenge of realzing a brighter gloss range through new processing technology.

At this time, we further developed our original multi-stage multi-nip machine and have succeeded in creating an innovative gloss by combining processing technology based on the designer’s sense.

Presented at "Premiere Vision"

"ULTRA RUGANO™" was exhibited anonymously as a prototype at the Paris Exhibition held in July 2015, and test sales were conducted in some European markets. The market response to the preliminary sales promotion was extremely positive, and we have already received a mass-production contract from a top European fashion house, giving us a solid response to this high and unexpected evaluation. In response to this evaluation, we have completed preparations for full-scale mass-production machine development and mass-production systems. At the Premiere Vision held in Paris in September 2015, we announced our product to the world, and we will begin full-scale sales of "ULTRA RUGANO™" in Japan and overseas during the 2016-2017 fall and winter season.

Special Features of " ULTRA RUGANO™"

- An innovative and bright lustrous material with an elegant mirror-like gloss.

- A fabric that retains flexibility, but is not flat and hard, and has a draped feel.

- A base material that can be developed with a variety of thin and medium fabric materials such as chemical fiber, synthetic fiber, and composite materials.

- A base material that can be developed with a variety of thin and medium fabric materials such as chemical fiber, synthetic fiber, and composite materials.

- Excellent washing durability and maintains texture and surface feel even after washing.

Brand logo

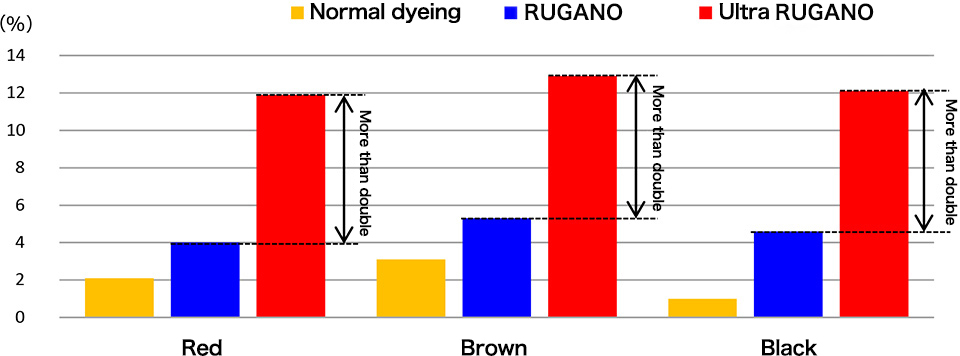

Glossiness of new areas

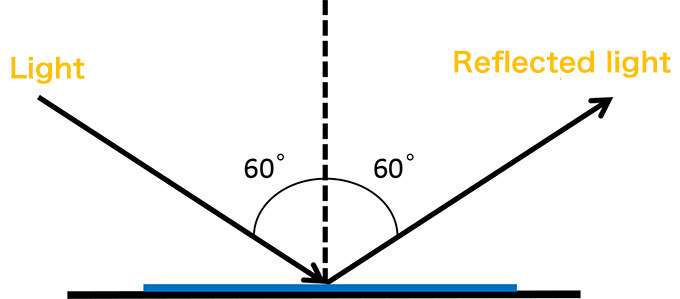

- Measurements are based on JIS (Japanese Industrial Standard) gloss measurement.

- The amount of reflection is measured with 100 as the incident light at 20, 60, and 85 degrees.

- Conventional RUGANO is a fabric that is about twice as reflective as normal dyed fabrics, but "ULTRA RUGANO™" is a fabric that is far more reflective than conventional RUGANO. (More than twice that of conventional RUGANO).

Measurement method of high brightness (reflection amount)

High brightness (reflectance) measurement

Applications

ashion clothing, sports clothing, bedding, general interior, bags, shoes, etc.

Photo comparison of " ULTRA RUGANO™" vs. normally dyed cloth

[Representative Material Comparison (20d Nylon Taffeta)]

The special processing technology newly developed (left picture) allowed for a glossy appearance with an improved reflection on the lightweight nylon taffeta used for down jackets, etc. (right picture is normal dyeing).